The AP100 is a high volume, ultra pure fog machine using liquid nitrogen and Deionized Water or WFI water to create about 15.5 cubic meters of fog per minute at a fog density of 1520 ml per minute for larger clean rooms, as well as stages and theaters. It is designed with a 316L stainless steel with an electro-polish finish. The AP100 can quickly produce large volumes of stage fog for theater and 3D theaters. The fog output would be used in large sterile rooms, large ISO suites and large semiconductor clean rooms during a 70 minute operating cycle. The AP100 Ultra Pure Fogger complies with USP 797 and ISO 14644-3, Annex B7 and Federal Standard 209E to visually describe airflow, patterns, direction, balance, dead zones and velocity for 3D airflow modeling in large ISO suites, large sterile rooms and large clean rooms. No other ultra pure fogger is capable of this fog volume, which due to purity, can also be used for theatrical stage fog. No contamination is created and no clean up of any kind is required after visualizing the airflow. The fog evaporates back to the same air we breathe.

AP100 Ultrapure Fogger

Description

AP100, Ultra Pure Cleanroom Fogger: 15.5 Cubic Meters / Minute for 90 minutes operation, 1520 ml per minute of Fog Density using 2 internal water heaters and 4 fog outputs

Smoke Studies and smoke tests use an LN2 ultrapure fogger to visualize airflow patterns and turbulence!

Watch video of the UltraPure Cleanroom Fogger

Ultrapure nitrogen foggers are used to provide high levels of fog in clean rooms, sterile rooms and ISO suites. It is also a very safe alternative for use as theatrical stage fog, replacing glycol foggers, which are not safe to breathe on stage. Liquid nitrogen is boiled to generate high levels of nitrogen molecules, which are mixed with de-ionized water or water for injection to produce an ultrapure fog at 15.5 cubic meters per minute for 90 minutes. More than 30 feet of visible airflow is provided, about 1162 cubic meters of ultra pure fog during a fog cycle. 100 liters of ln2 is filled into a dual wall LN2 Dewar and water is filled into a stainless steel, dual heating chamber. Water is brought to a high temperature and the liquid nitrogen boils at room temperature, allowing the vapor from both liquids to form a very visible, ultrapure, fog. The boiling process creates pure nitrogen molecules and water molecules, which combine to create a nominal 2-3 micron fog vapor droplet at a very high fog density. The high purity fog exits in the airflow with minimal disturbance of airflow. The AP100 provides the greatest visible air flow distance of 30-40 feet to visualize airflow turbulence and patterns. Video, 3D airflow modeling and stage fog is easily generated as the dense fog provides superb contrast between the fog and back ground. No contaminants are released into the airflow and the nitrogen/water fog evaporates back to the same elements we breathe. 16 Meg Ohm DI water is typically used, but WFI water can also be used, and in theatrical applications, tap water can be used. The AP100 provides increased visual distance of the moving airflow in large clean rooms.

Performance of the AP100 Cleanroom Ultra Pure Fogger– Request a Quote

|

Cleanroom Ultra Pure Fogger Features – Request a Quote

AP100 Ultra Pure Fog for Smoke Studies in Clean Rooms

- Adjustable, ultra pure airflow visualization to describe direction, velocity and patterns in airflow

- Modular design for simple operation and maintenance

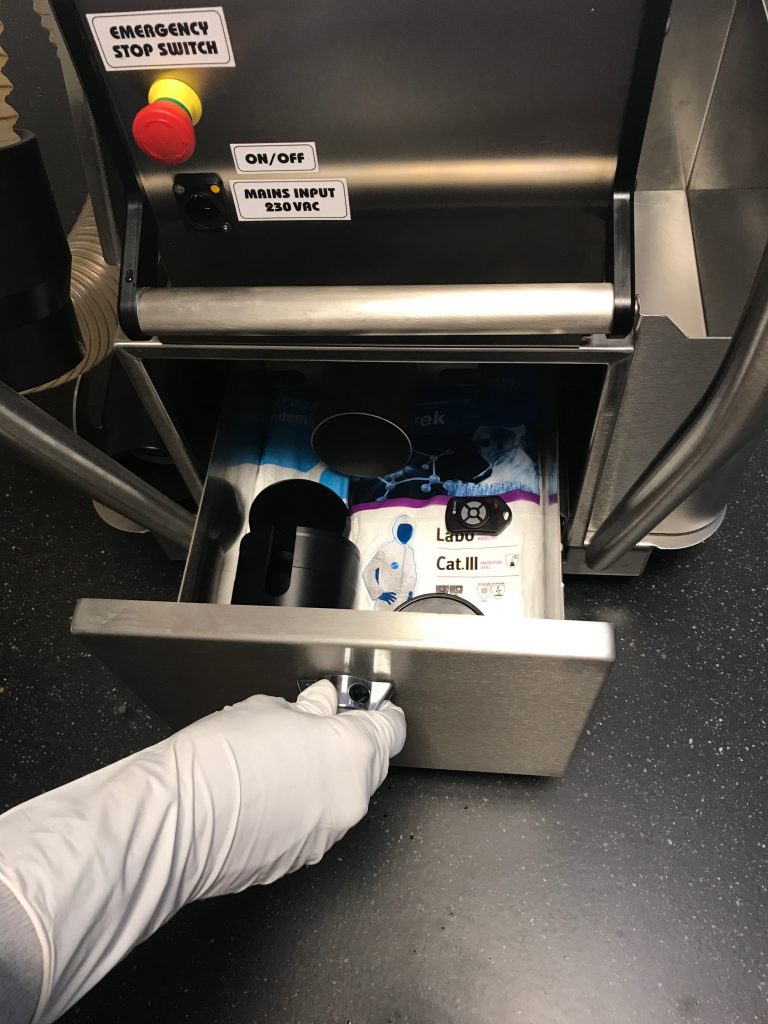

- Direct fogger control or remote control by wireless key fob to operate behind a closed wall or closed area

- Visualization of unwanted gas emission locations and dead zones

- Supports test for ISO 14644-3 ANNEX B7 airflow visualization

- Supports analysis for Pharmaceutical USP 797 Guidelines and airflow visualization

- Supports NSF 49 National Safety Foundation for airflow visualization

- Supports the future USP 800 Hazardous Drug Compounding for airflow visualization

- Supports airflow visualization test for Semiconductor Semi-Standards Guidelines

- Tracking routes of unwanted air flow infiltration into clean rooms

- No contamination created, no contamination left behind

- No cleanup of any kind after fog visualization

- Superb 3D airflow modeling capabilities with high density fog

- Very low fog exit pressure, no exit turbulence as fog enters airflow

- Compact, transportable, shipping case

- Fog stream output and fog rake output

- For use in sterile rooms, ISO suites and clean rooms

- High density fog visualization provides the best airflow visualization of any fog generator in the market

- Exhaust and ventilation studies around wafer handling systems

- Air balance studies in Pharmaceutical suites and clean rooms

Cleanroom Ultra Pure Fog Generator Advantages – Request a Quote

- Highest fog density by converting 1520 ml of liquid per minute to an ultra pure fog

- Very dense, Stream Fog from four, 5 meter x 80 mm fog hose outlets

- Greatest visible airflow distances of 30 plus feet

- Highest volume of ultra pure fog at 15.5 cubic meters per minute

- Total volume of 1162 cubic meters of ultra pure fog per operating cycle

- Longest operating time of 90 minutes

- No contamination is created, no cleanup is required, no contamination to the process

- No turbulence created as fog enters the airflow

- Roller castors for easy movement over floor

- Four 80mm fog hose outlets

- User Friendly display and touch pads

- Stainless steel contacts the LN2 and DI Water for best purity of fog

- very low fog exit pressure that does not create a disturbance to airflow

- Optional LED Light accessory to provide high contrast between visualized airflow and background

- Optional 350 mm Fog Nozzle accessory to spread standard fog stream out as it enters air flow

- Optional 500 mm Fog Nozzle accessory to spread standard fog stream out faster as it enters air flow

- Optional Y Adaptor accessory to convert single fog output into two separate fogger hoses for two separate fog inputs to your clean room

- Optional T Adaptor accessory to convert single fog output into two Fog Curtain Wands to spread fog pattern out across wide area

- Optional 10 Meter Transparent Fog Hose to use with Y Adaptor

- Optional 1.3 Meter or 2 Meter Fog Curtain Wands to spread fog stream out into a wide fog pattern

- Easy DI Water and LN2 fill up

* Fog distance measured at 40% humidity and air velocity of 90fpm. Visual fog distance decreases as humidity decreases or as airflow velocity increases.