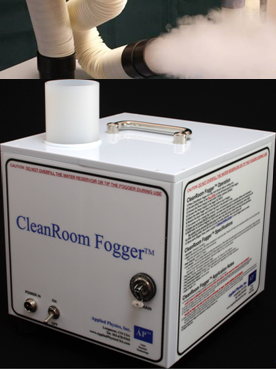

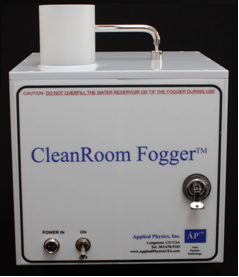

A DI Water Fogger uses ultrasonic devices to create a pure fog to visualize airflow patterns and turbulence in smoke studies of pharmaceutical ISO suites, Bio-Safety Cabinets, medical rooms and clean rooms; providing compliance with USP 797 Pharmaceutical in-situ airflow analysis and the proposed USP 800 Hazardous Drug Compounding, Airflow Recovery Tests of ISO 14644-3 Annex B12, air flow tests for NSF Standard 49, National Sanitation Foundation; Visualization Tests for ISO 14644-3 Annex B7 and Semiconductor clean rooms, Federal Standard 209E.