Ultrapure-Fogger

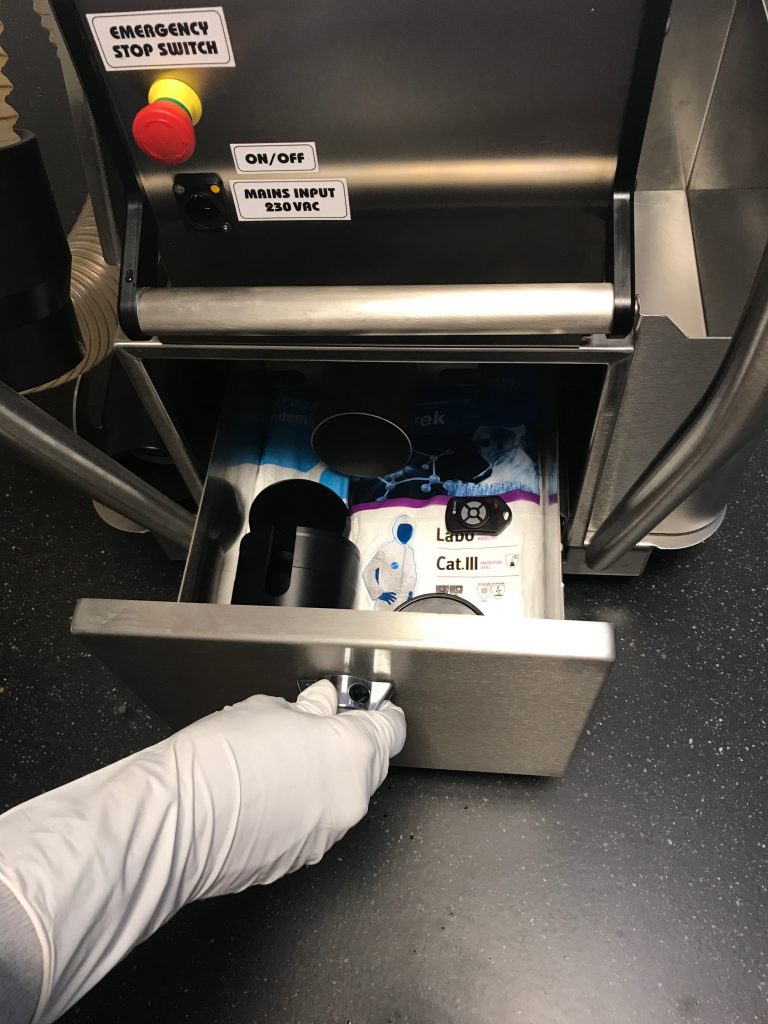

The AP100 is a high volume, ultra pure fog machine using liquid nitrogen and Deionized Water or WFI water to create about 15.5 cubic meters of fog per minute at a fog density of 1520 ml per minute for larger clean rooms, as well as stages and theaters. It is designed with a 316L stainless steel with an electro-polish finish. The AP100 can quickly produce large volumes of stage fog for theater and 3D theaters. The fog output would be used in large sterile rooms, large ISO suites and large semiconductor clean rooms during a 70 minute operating cycle. The AP100 Ultra Pure Fogger complies with USP 797 and ISO 14644-3, Annex B7 and Federal Standard 209E to visually describe airflow, patterns, direction, balance, dead zones and velocity for 3D airflow modeling in large ISO suites, large sterile rooms and large clean rooms. No other ultra pure fogger is capable of this fog volume, which due to purity, can also be used for theatrical stage fog. No contamination is created and no clean up of any kind is required after visualizing the airflow. The fog evaporates back to the same air we breathe.

-

Cleanroom-Ultrapure-Fogger-AP35.pdf AP35 Utrapure Fogger is designed with a 316L Stainless Steel body and enclosure and electro-polish finish. It uses liquid nitrogen and Deionized Water or WFI water to generate about 5 cubic meters of ultra pure fog per minute with a fog density of 571 ml per minute for smoke studies. LN2 fogger technology was developed in 2001 for smoke studies and air flow characterization in clean rooms. The fog output is adjustable from 2-5 cubic meters per minute. The AP35 complies with Semiconductor clean room guidelines, USP 797 Insitu Airflow Analysis and ISO 14644-3 visual airflow requirements to provide 3D airflow modeling in clean rooms, ISO suites, sterile rooms and medical rooms. The AP35 costs nearly the same as competing ultra pure fog generators, yet provides 3X more fog volume, 2X more fog density and 2X more visual airflow distances than competitive LN2 foggers.

Cleanroom-Ultrapure-Fogger-AP35.pdf AP35 Utrapure Fogger is designed with a 316L Stainless Steel body and enclosure and electro-polish finish. It uses liquid nitrogen and Deionized Water or WFI water to generate about 5 cubic meters of ultra pure fog per minute with a fog density of 571 ml per minute for smoke studies. LN2 fogger technology was developed in 2001 for smoke studies and air flow characterization in clean rooms. The fog output is adjustable from 2-5 cubic meters per minute. The AP35 complies with Semiconductor clean room guidelines, USP 797 Insitu Airflow Analysis and ISO 14644-3 visual airflow requirements to provide 3D airflow modeling in clean rooms, ISO suites, sterile rooms and medical rooms. The AP35 costs nearly the same as competing ultra pure fog generators, yet provides 3X more fog volume, 2X more fog density and 2X more visual airflow distances than competitive LN2 foggers.